CONTINOMIXX

CONTINUOUS DOUGH PRODUCTION SYSTEM

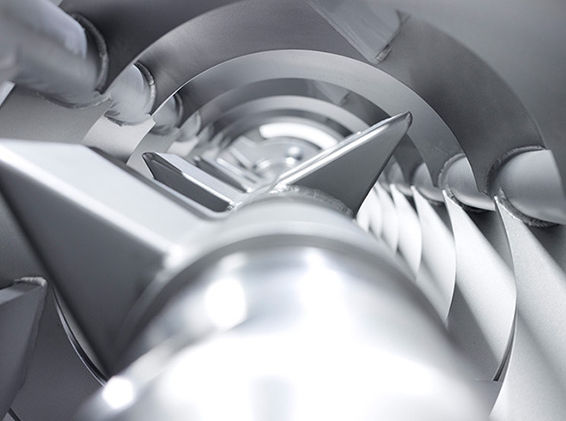

This plant consists of a continuous dosing system, a pre-kneader and the newly patented generation of the continoMIXX premium system.

In the pre-stage, all raw material components are pre-kneaded, the post-kneading in the premium system continoMIXX ensures an ideal and flexible dough production. While in the pre-kneader within seconds a homogeneous pre-dough is created, which can immediately be fed to further processing of the dough, the premium system continoMIXX combines homogeneous mixing with effective kneading.

In addition to direct kneading in the ContinoMIXX, we work with various technical solutions for the preliminary stage, such as mixing pump technology, high-speed mixers and the ContinoJET, which is licensed by AHK outside the USA / Australia.

In this innovative high-pressure kneading process, the dough preparation by means of a rotary nozzle is carried out by intensive wetting of the flour particles with a high-pressure water jet (> 120 bar). The particles form a homogeneous dough within seconds.

ADVANTAGES

• Two independently adjustable tools (kneading and feeding)

• Maximum flexibility in hourly performance and kneading intensity

• Optimal kneading even with very high additions of back doughs / residual doughs

• Product-saving output of the finished dough optionally continuously or dosed

• Kneading of different doughs without changing tools = fast recipe change

• Cooling in the double jacket prevents digester heating

• Increased water absorption capacity thanks to ContinoJET, which is licensed by AHK outside the USA / Australia.

* longer durability

* Better volume

* More flavor

* Reduction of ingredients costs

•Very short mixing time with ContinoJET, which is licensed by • AHK outside the USA / Australia.

• Reduced power consumption compared to comparative machines

• Automatic cleaning according to WIP principle

• Little need for space

OPTIONS

• Three power ratings: 1 - 3 t, 2.5 - 5 t and 4 - 8 t per hour

• Efficient cleaning according to WIP principle

• Automatic dispensing systems for all ingredients

• Automated dough feed